Roller Magnetic Separation Machine

OUR PRODUCTS:

- Magnetic Rod – 10000 Gauss Magnetic Rods

- Grill Magnetic Separator for Hopper

- High Intensity Plate Magnetic Separator

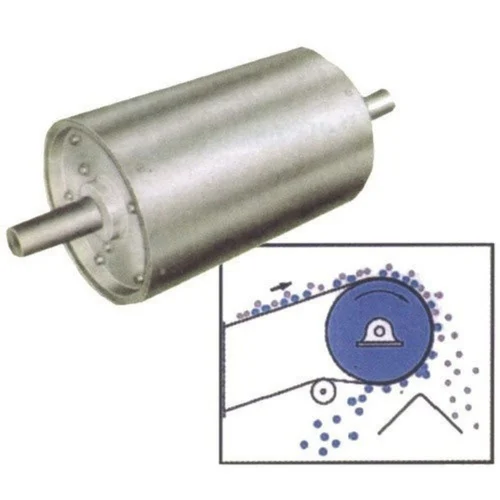

- Drum Magnetic Separator/Magnetic Pulley

- Drawer Magnetic Separator

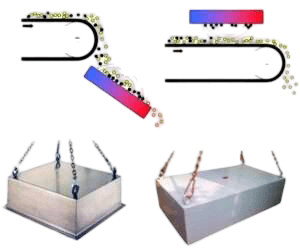

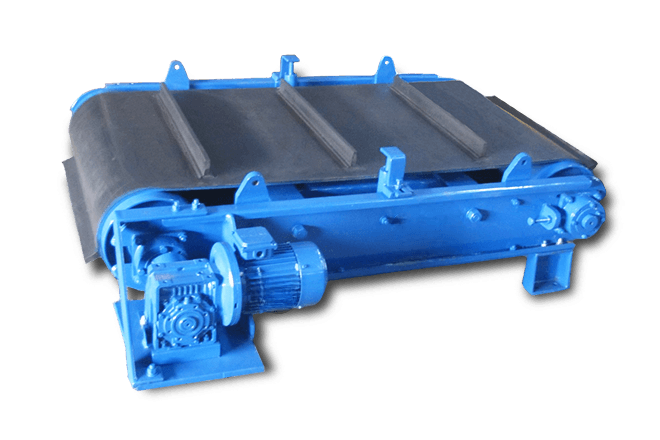

- Overband Magnetic Separator

- Roller Magnetic Separator

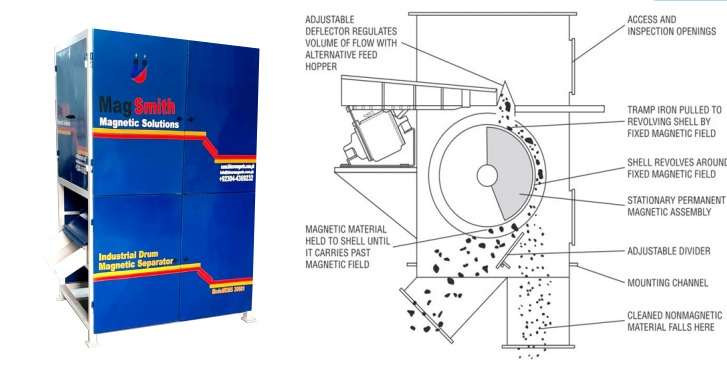

- Drum Magnetics Separation Machine

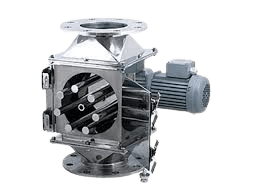

- Rotatory Magnetic Grid Separator

- Hump Magnets

- Liquid Trap Magnetic Filter

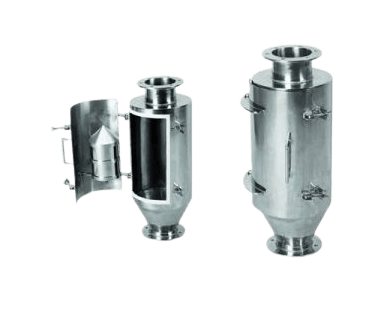

- Bullet Magnet

- Wet Drum Magnetic Separator

- Electro-Magnets

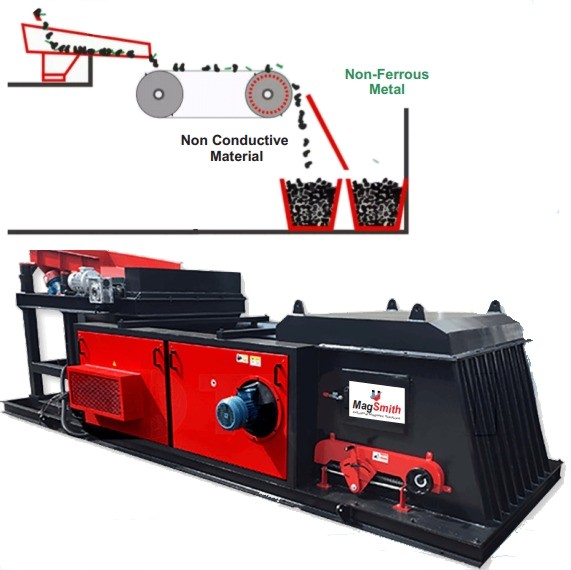

- Eddy Current Separator

- 10000+ Gauss Rods

- Grill Magnetic Separators

- Drum Magnetic Separators

- High Intensity Plate Separators

Roller Magnetic Separation Machine

Our Roller Magnetic Separation Machine is designed to eliminate weak magnetic particles like fine metal powder, paramagnetic material, and stainless-steel impurities from the product. This type of separator is mainly used to protect machines and quality of your product to remove ferrous particles and purify products.

Working Principle

Applications

Our Roller Magnetic Separation Machine is widely used in various industries, including:

- Food Processing (spices, Rice Mills, Sugar Mills, Flour Mills, Salt, Glass, Plaster of Paris, Cement, Tobacco etc.)

- Pet-Bottle Recycling Industry

Features and Benefits

Our Roller Magnetic Separation Machine offers several features and benefits, including:

- Materials which can be separated out very Fine Metal Powder up to micron level

- Stainless Steel Particles

- Weak Magnetic Metal(which are unable to separate with

ordinary magnet) - Para-magnetic Material

- Easy to install

- Continuous automatic cleaning

- Enclosed design to avoid pollution and dust

- High efficiency rate

- Customization available to fit your existing equipment

How it Works

Roller Magnetic Separation Machine works:

Step 1: Material Feeding

The material to be separated is fed onto the roller of the separator.

Step 2: Magnetic Field Generation

The roller is made of a permanent magnetic material that generates a strong magnetic field.

Step 3: Ferrous Particle Attraction

As the material flows over the roller, the ferrous particles are attracted to the magnetic field and are held onto the roller.

Step 4: Non-Ferrous Material Separation

The non-ferrous materials are not affected by the magnetic field and continue to move along the conveyor belt or vibratory feeder.

Step 5: Ferrous Particle Removal

The ferrous particles that are attracted to the magnetic field are removed from the roller by a self-cleaning mechanism, which ensures that the roller remains clean and free of debris.

Step 6: Continuous Operation

The Roller Magnetic Separation Machine is designed for continuous operation, allowing for efficient and effective separation of ferrous and non-ferrous materials.

Our Clients

Our products are trusted by big Pakistani companies like:

Why Choose MagSmith Magnetics Industry?

At MagSmith Magnetics Industry, we are committed to providing high-quality products and services to our clients. We have a proven track record of delivering tailored-made solutions to meet the specific needs of our clients.

Our company will provide permanent (lifetime) after sales service

Contact Us

Got a quotation on need a quote? Our Magnetic Experts are here to offer fast, personalized guidance for all your magnetic separation needs. Simply fill out the form below, and one of our specialists will quickly reach out to assist you.