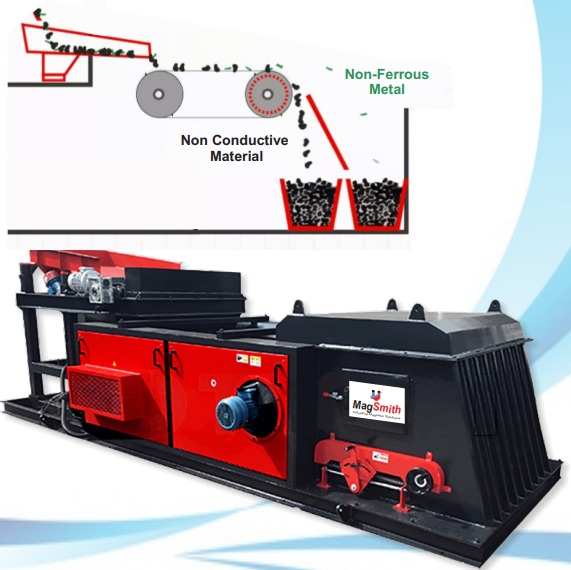

Eddy Current Separators

OUR PRODUCTS:

- Magnetic Rod – 10000 Gauss Magnetic Rods

- Grill Magnetic Separator for Hopper

- High Intensity Plate Magnetic Separator

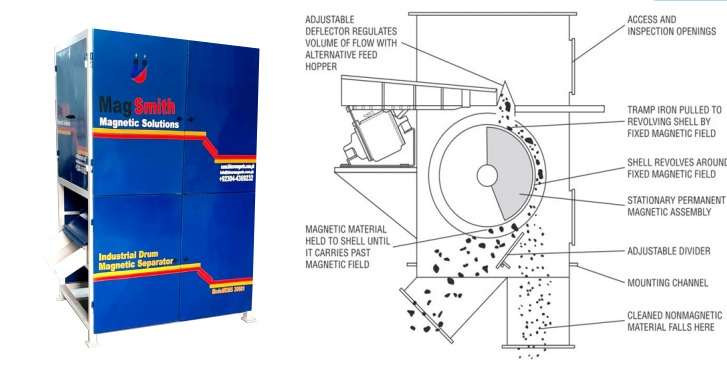

- Drum Magnetic Separator/Magnetic Pulley

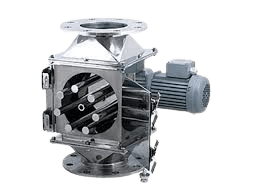

- Drawer Magnetic Separator

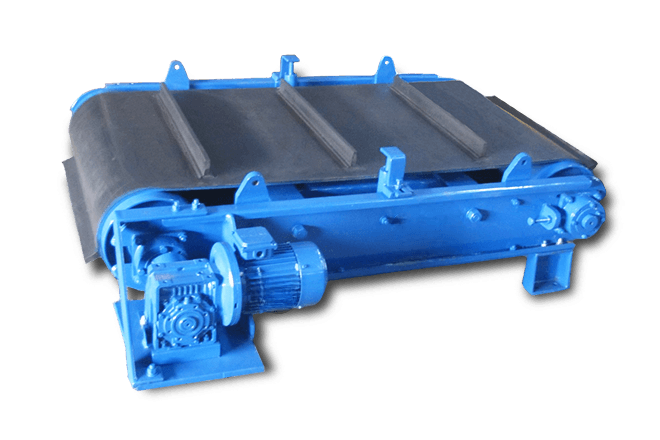

- Overband Magnetic Separator

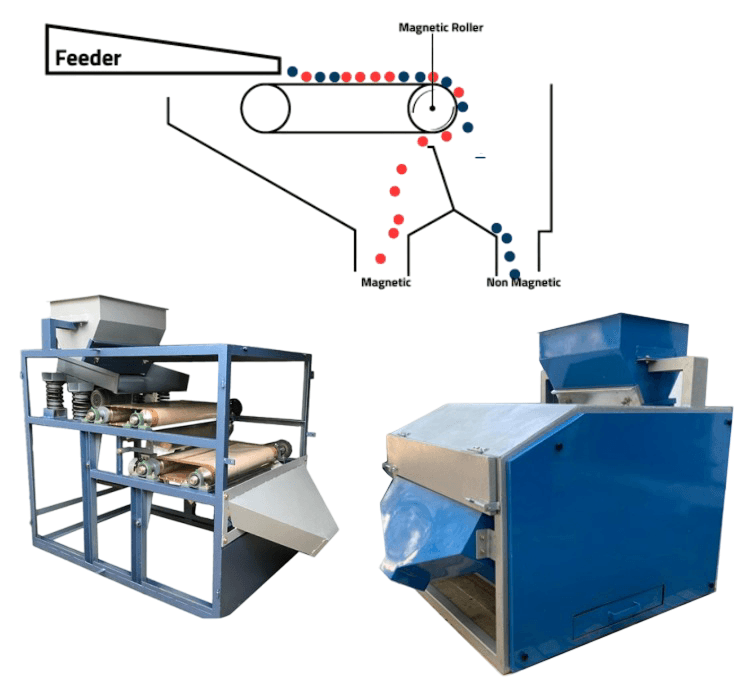

- Roller Magnetic Separator

- Drum Magnetics Separation Machine

- Rotatory Magnetic Grid Separator

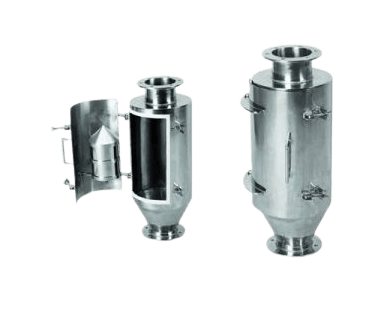

- Hump Magnets

- Liquid Trap Magnetic Filter

- Bullet Magnet

- Wet Drum Magnetic Separator

- Electro-Magnets

- Eddy Current Separator

- 10000+ Gauss Rods

- Grill Magnetic Separators

- Drum Magnetic Separators

- High Intensity Plate Separators

Eddy Current Separators

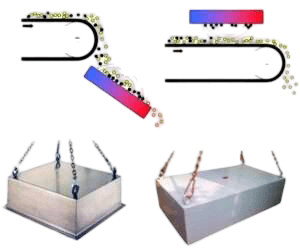

Our Eddy Current Separators are prominently used in industries as a separator of non-ferrous metals from mixed wastes and other mainstream materials. These separators are widely used in municipal solid waste recycling lines, scrap residues, and other project lines.

How it Works

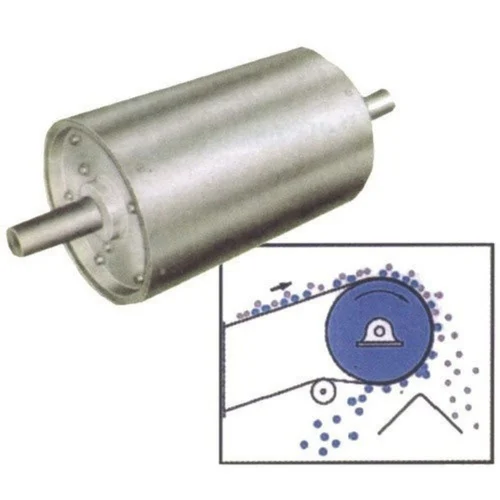

Our Eddy Current Separators work on the principle of eddy current separation. The separator consists of a high-speed magnetic rotor system installed at the discharge end of a conveyor belt. The rotor revolves at high-speeds during working, whilst the outer drum cover rotates at the speed of the eddy current belt conveyor.

As the rotor spins, electric current is induced into the conducting metals of the flow. This current creates a magnetic field, which opposes the field created by the rotor, repelling the conducting metals over a pre-positioned splitter plate, completing the separation process.

The remaining materials such as plastics, glass, and other dry recyclables will simply free-fall over the rotor, separating them from the repelled metals.

Applications

Our Eddy Current Separators are widely used in various industries, including:

- Municipal solid waste recycling lines

- Scrap residues

- Other project lines

Advantages

Our Eddy Current Separators offer several advantages, including:

- High efficiency in separating non-ferrous metals

- Easy to install and maintain

- Compact design

- Can be customized to suit specific application requirements

How it Works

Here’s a detailed explanation of the working of the Eddy Current Separator:

Step 1: Material Feeding

The material to be separated is fed onto the conveyor belt of the Eddy Current Separator.

Step 2: Rotor Rotation

The high-speed magnetic rotor system is installed at the discharge end of the conveyor belt. The rotor revolves at high-speeds during working.

Step 3: Eddy Current Generation

As the rotor spins, electric current is induced into the conducting metals of the flow. This current creates a magnetic field.

Step 4: Magnetic Field Interaction

The magnetic field generated by the eddy current interacts with the magnetic field created by the rotor. This interaction causes the conducting metals to be repelled.

Step 5: Separation

The repelled conducting metals are separated from the non-conducting materials and are discharged over a pre-positioned splitter plate.

Step 6: Non-Conducting Material Discharge

The non-conducting materials, such as plastics, glass, and other dry recyclables, simply free-fall over the rotor and are discharged separately.

Our Clients

Our products are trusted by big Pakistani companies like:

Why Choose MagSmith Magnetics Industry?

At MagSmith Magnetics Industry, we are committed to providing high-quality products and services to our clients. We have a proven track record of delivering tailored-made solutions to meet the specific needs of our clients.

Our company will provide permanent (lifetime) after sales service

Contact Us

Got a quotation on need a quote? Our Magnetic Experts are here to offer fast, personalized guidance for all your magnetic separation needs. Simply fill out the form below, and one of our specialists will quickly reach out to assist you.