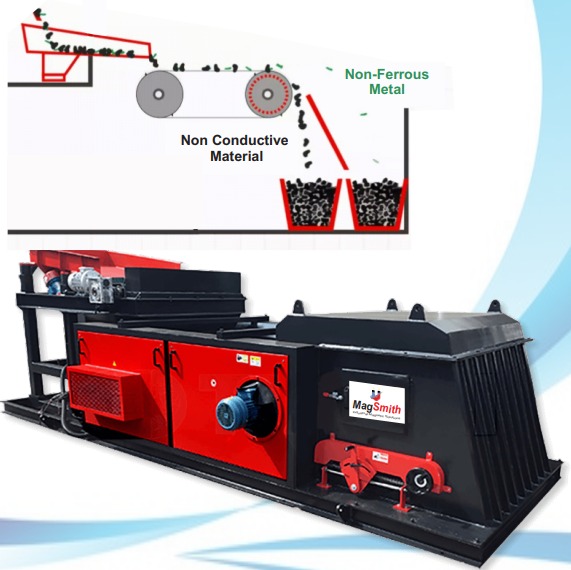

Eddy Current Separator For Non-Ferrous Metal

OUR PRODUCTS:

MagSmith Magnetic Industry is the pioneer in magnetic separation technology in Pakistan & biggest manufacturers of Eddy Current Separators which are prominently used in industries as a separator of non-ferrous metals from mixed wastes and other main-stream materials municipal solid waste recycling lines, scrap residues and other project lines.

We manufacture the eddy master class eccentric rotor design to ensure the full efficiency of eddy current effects on the rotor shell, that separates about 97% of your total non-ferrous impurities.

For These Industries:

Working Principle

In an eddy current separator, there is a short belt of conveyors that has its

drive located at the return end and a high-speed magnetic rotor system

installed at the discharge end. This rotor, which is positioned within a

separately rotating non-metallic drum, revolves at high-speeds during

working, whilst the outer drum cover rotates at the speed of the eddy

currents belt conveyor

For These Industries:

- ALumminium Can Separation

- Municiple Waste Recycling

- Pet-Bottle Recycling