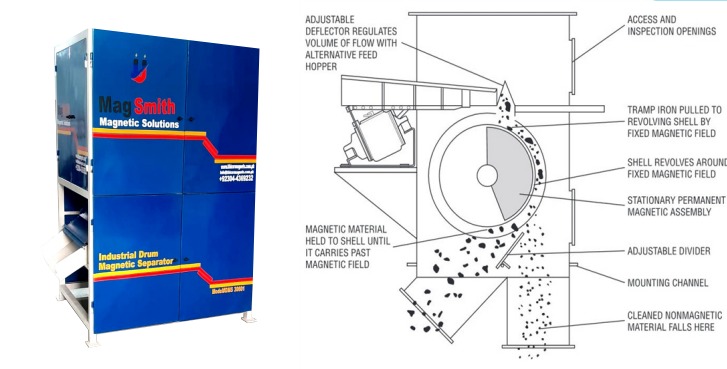

Drum Magnetics Separation Machine

OUR PRODUCTS:

Our Permanent Drum type separator which is most and widely used separating tramp iron from nonmagnetic material processed in large quantity, for the purity of end products, recovery of metal having commercial value and protection of processing plant and machinery. Single Drum Type Magnetic Separator is widely used in all the processing industry for separation of iron contamination from minerals ,chemicals, food, grains, sand, plastic fertilizers, slag,ores and in many more products

For These Industries

- Pet-Flakes Recycling Industries

- Iron Ore Processing Industry

- Mining Industry

- Food Processing Industry

- Wooden Chip Processing Industry

- Metal Recycling Industry

• Designed for continuous separation and cleaning, with no need for product flow to be shut down or otherwise interrupted.

• Available with stainless steel drum, mild-steel, or stainless steel housings to suit your application needs.

• MagSmith Magnetic Industry supplies custom transitions to match round, square, or rectangular spouting, allowing for a simple, secure fit with your existing equipment.

• Available in 3 grades of rare earth magnets.

• Ideal for high-flow, heavy-contamination applications.

• Direct drive is standard with an optional variable speed control based on your application needs.

Working Principle:

We also offer Free Trial of your Product at our Site